Adjusting and improving the Neutral Finder

- Home

- Adjusting and improving the Neutral Finder

-

By: admin

- 0 Comments

This work is much easier to complete while the engine is out of the car and is certainly something that should be investigated during an engine overhaul. With many of these assemblies approaching fifty years old – many different people may have dismantled and adjusted parts each with varying skill levels. Measurement of these moving parts is not covered in any of the manuals because it was rarely required. Now that the parts are so much older, we have to correct wear caused by corrosion and incorrect assembly.

Incorrect adjustment of the neutral selector can cause gears to jump out of the selected position. Many owners spend a lot of time investigating the neutral selector when the cause of jumping gears lies elsewhere. While jumping fourth gear is common, it is not common for the other gears to jump out of their selected positions into the adjacent neutral point. If this happens, double check the oil level in the gearbox. If the problem persists, disconnect the neutral finder completely, then drive the car to see if the defect has been eliminated.

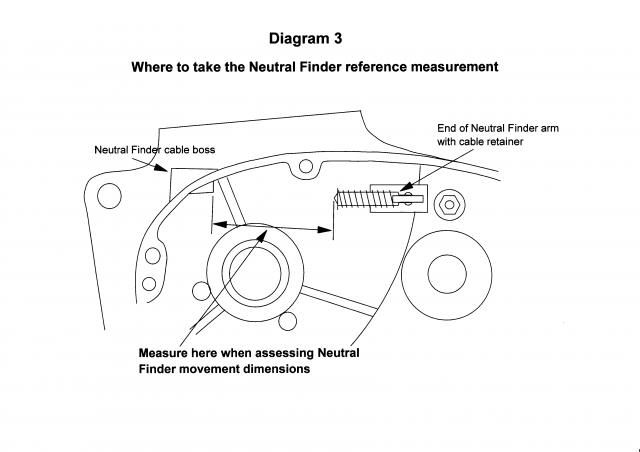

The workshop manual does not cover setting of the neutral selector in any detail. Although, surprisingly, it is covered quite well in the Owners manual. A Sachs technical bulletin is available on our website giving their version from the early days of Messerschmitts. Located behind the clutch drum, it is a very simple lever system made out of pressed and riveted components. With the selector quadrant and detent arm finally assembled, you might like to check the movement and clearance position of the neutral finder IN EACH OF THE GEARS. There is good reason to take extra care in the setting of this device. To identify the travel of the operating arm, I made up a brazing rod neutral finder cable that I could use to operate the mechanism, and carefully measured the distance between the inner boss of the cable mount on the crankcase and the end of the cable carrier on the neutral finder

To complete the measurements, I used a vernier calliper, and the arrangement is shown in diagram 3. Firstly, I found the contact position of the neutral finder cam with the neutral finder quadrant and measured the distance between the two points for each of the gear positions 1st trough 4th. Next, I measured the distance between the same two reference points once the quadrant had ‘just’ been knocked back into neutral by pulling on my brass rod. I noticed that the clearance positions of my neutral finder varied by about 2mm, and the ‘knock back’ positions by about 1 mm more. (And my components didn’t appear to be worn!)

Although these variations in movement seem very small, let me remind you that, particularly in 4th even slight movement of the neutral finder arm, once contact with its cam has been made, will force the selector quadrant out of it’s full detent position. That starts to disengage the dog clutch! That 1 mm you have questioned is more than enough to move the 4th gear dog clutch half out of engagement. (This may well be one of the reasons for wear on the dog clutches and premature jumping out of gear)! I think that the total cable movement I can get with my neutral finder trigger on the gear lever is 11mm! and 2mm in 11mm is almost 20%! The message I wish to impart is that adjustment of the neutral finder cable is sensitive, AND CRITICAL!

Using this method to set up the trigger mechanism will make it very easy to set when you finally do get the engine back in the car. Couple up the neutral finder cable, and adjustment is really dead easy. You just make the distance between your two reference points, the inner boss on the crankcase and the end of the cable carrier on the neutral finder arm, slightly (say about 1mm) MORE than the MAXIMUM length of the neutral finder clearance distance in any of the gears, and you then KNOW that the Neutral finder mechanism can’t be interfering with the detent mechanism. (Hint, you can always make up a bit of stick the right length and use it during cable adjustment!)

The total variation in the clearance position of my Neutral Finder was about 2mm. If the variation exceeds 2mm you may find that you need to ‘massage’ the finder cam slightly to get the finder to work in all gears. I have not had to do that, but the design of pressed and riveted construction cannot be particularly accurate. It may be a further potential original cause of gear jumping if these distances vary wildly, causing the neutral finder to force the detents out of full engagement in some gears, when apparently properly adjusted in others. If you need to do this – be careful – the geometry has a high mechanical gain, and a little metal removed will have a lot of clearance effect.

Prev Post

Internet Membership FAQ

Next Post

Gearbox lubrication and..

Related Post

- April 4, 2018

Tri-Tech Replica KR200 Brochure 1997

- March 7, 2018